ROOF RACKS AND CARGO CARRIERS FOR PROFESSIONALS

State-of-the-Art Roof Rack Basket

The AluRack is customised for all types of vehicles, ranging from normal vans with a short or long wheelbase, standard or high roof, pickups, trucks and other commercial vehicles.

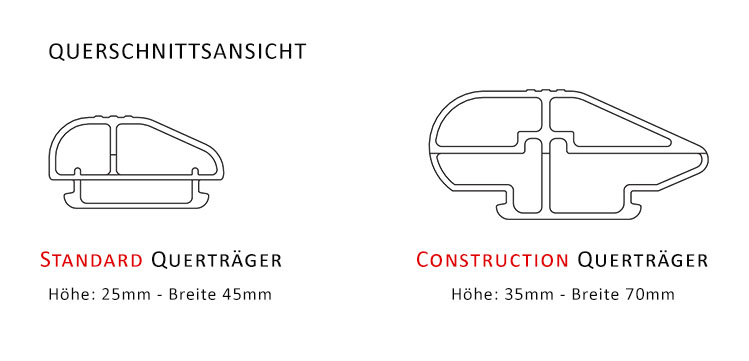

The aerodynamic aluminium roof rack offers increased efficiency and safety by perfectly adapting to the shape of the roof, also giving the vehicle a dynamic look. Crossbars are available in two variants: Standard, and a heavy duty edition to carry even heavier loads without generating driving noise. The AluRack also offers a wide range of useful accessories.

strengthens the side rails by connecting the top and bottom rail with a bolted aluminum assembly instead of plastic.

Quickly secure ladders for transport with a turn of a lever.

Transport pipes and long materials with ease. Conduit tube keeps your items dry, clean and safe. 3m+ conduit tubes are shippable in 2 or 3 sections.

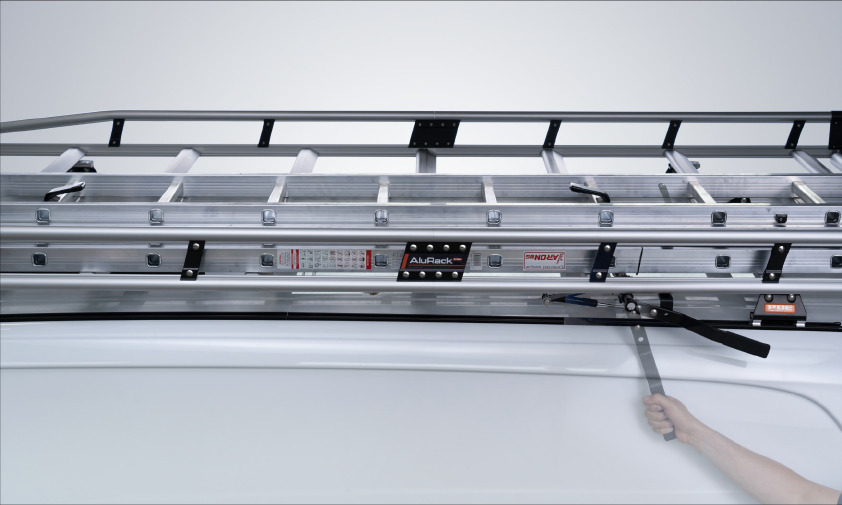

preserves your vehicles roof, holes or gutter. NO DRILLING OR WELDING!

Ergonomically the best solution for mounting ladders on roof racks

Multifunctional accessories for every purpose

Environmentally friendly: 100% recyclable materials

Corrosion-free anodised surface - resists all weather conditions

Modern design, creating a dynamic look. Uses pre existing mounting points

Very light with a dead weight of less than 20 to 30 kg (depending on vehicle), it is about 30 % lighter than a comparable steel rack

The aerodynamic shape reduces fuel consumption, wear and tear and generates hardly any driving noise.

The aluminium construction (maximum 35 % of the permissible roof load) allows a higher payload to be carried on the carrier

The loading tube and the S-Clamp quick-locking system allow quick and safe transport of ladders and equipment

AluRack Testing Success

AluRack Crash Test

The AluRack has successfully completed a dynamic city crash test (according to ISO 11154, Annex E) at TÜV SÜD in the Czech Republic. The roof rack was mounted on the roof of a van and loaded with the maximum permissible load of 181 kg (dead weight of the roof rack 19 kg). At a speed of 18 km/h, a frontal impact occurred with the test sled. The load and the roof rack remained unchanged in their positions on the roof during this impact – proofing the high safety standards.

AluRack Durability Test

As part of a test by Flanders' Drive, the durability of the AluRack (width 1650 mm) was tested at time-lapse speed on a hydraulic test rig with uniaxially applied force. The test consisted of two parts: In the first part, a transporter with accelerometers was driven over a test track. In the second part, the result of the vibrations measured in the test was converted into signals that controlled a hydraulic test unit on which the AluRack was mounted. The function of the Alu-Rack with a distributed payload of 150 kg was maintained during the entire duration of the durability test.

AluRack Construction

Heavy Duty Edition

While maintaining the aerodynamic shape, the load capacity is increased by even stronger cross beams. The low weight in combination with the structural stability makes it possible to use, or even exceed, the maximum roof load of the vehicles, while also reducing driving noise.

AluRack Pickup - The roof rack solution for pickups

die flexibelste Dachträgerlösung für Pickups auf dem Markt

The patented construction is mounted on the tail lift, no drilling work required. The lightweight yet robust design optimises the load capacity of any pickup.

- Lightweight aluminium construction - saves fuel consumption

- Wide range of optional accessories to help with loading and unloading

- No drilling work required

- Load stops can be easily moved and are equipped with a hook to serve as lashing points

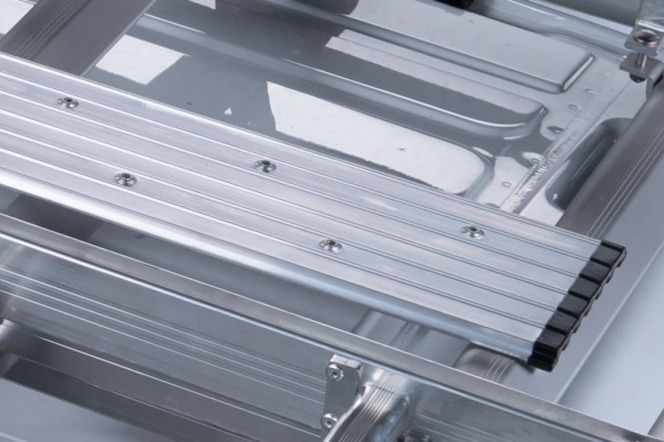

- Non-slip rubber surface crossbars

- Mounting kits for pickups with an installed canopy are available

The Essential Roof Rack Solution

The AluBar roof rack consists of two crossbars, rails and mounting material. Available for all types of vehicles, size and application. Depending on the vehicle length, additional crossbars can be mounted on the rails. A variety of add-ons are offered, to fit specific requirements.

Our proprietary mountings system allows you to position your AluBars exactly where you need them on your vehicle, while protecting it’s roof and original mounting holes or gutter from damage.

Our aluminium crossbars are fabricated from our engineered extrusions, designed and produced in our own factories. Rubberised on top to prevent cargo from slipping and finished with ABS end caps for a sleek professional look.

AluBars come standard with our original design, rubberised cargo stops.

Outfit your AluBars with accessories that make daily tasks safer and save time and stress.

AluRack / AluBar Accessories

LED warning light with special mounting brackets to fit the cross bars

Rear loading roller for AluRackEasy to mount on the rear end of the roof rack, the loading roller makes loading and unloading of long objects much easier

Aluminium loading tubeLockable loading tube on both sides (2-5 m long, 125 mm cross-section)

Rear loading roller for AluBarEasy to mount on the rear end of the roof rack, the loading roller makes loading and unloading of long objects much easier

S-clamp - ladder fixture

The S-Clamp enables easy and efficient transport of lightweight stepladders and extension ladders on vehicles with low roofs. Reducing the duration of loading and unloading a ladder from an average of 240 seconds (4 minutes) to 20 seconds, i.e. by 80 %.

The ladder is secured with a gas spring-assisted hook. The front hook helps the user to position the ladder on the roof rack. By operating the handle, the rear hook sets up and fixes the ladder securely for transport. No straps or lashing straps are required. The ladder can be secured with a padlock if necessary.

Tailgate ladder for clamping

The PDE rear ladder offers additional convenience and safety when loading

and unloading your PDE roof rack system. This product is fabricated from

the same high-grade aluminum as our other products and utilizes

engineered features that preserve your vehicle and make installation simple.

MOUNT WITHOUT DAMAGING YOUR VEHICLE

The Aluminum Door Ladder product is mounted with a clamping system, avoiding

having to drill into the bodywork, preserving the integrity and resale value of your

vehicle. This lightweight product can easily be installed by one person and fits any

LCV. If you have a fleet or more than one of the same model of van, the Aluminium

Door Ladder can easily be moved from one vehicle to another.

HIGH-PERFORMANCE, SUSTAINABLE MATERIAL

Aluminum not only looks great but is corrosion-resistant and durable.

The aerodynamic design and low weight help reduce fuel consumption.

THE PERFECT FIT FOR YOUR VEHICLE

The PDE Aluminium Door Ladder is available for all LCV models including; Fiat

Ducato, Mercedes Sprinter, VW Crafter, Peugeot Boxer, Citroen Jumper, Opel

Movano, Nissan NV400, Renault Master, Iveco Daily and others.

Follow Ullstein Concepts